Mold Release Agent

> Precision and Special Chemistry >

Mold Release Agent

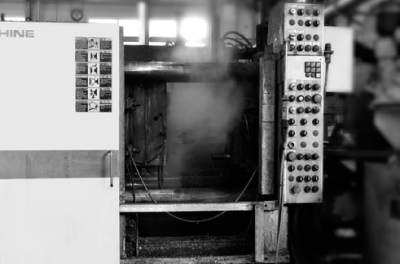

Release Agent for Die Casting

ALUB® series die casting release agents are categorized into each of product groups most suitable for aluminum, magnesium, zinc, copper, and squeeze casting. Therefore, we compose our products by working characteristic so that it can realize superb releasing performance under any working.

ALUB® release agent has remarkably improved fusion and mold contamination, which are the chronical problem in die casting process, and a user can get fine castings with shining surface. It can minimize general defect rate by contamination by fusion and/or mold, poor painting/coating, and inner air bubble.

Selection of ALUB® release agent is directly connected to the increase of your productivity and quality.

Automobile Interior Release Agent

Automobile interior release agent is used when giving pressing process to automobile interior products (e.g. fabric, non-woven fabric, carbon fiber, artificial leather, and so on). It is applied inside a hot die and exerts excellent performance for hot/cold pressing molding. In addition, it protects expensive equipment from thermal stress in any process and furthermore provides clean and improved surface finishing.

Releasing agent for internal automobile sheet is used for various pressing processes. When used efficiently, it can form thin and uniformed protective film; minimize mold corrosion; and improve economics and productivity.

Polyurethane Release Agent

Rubber Release Agent, Dusting agent

※ Release Agent

Releasing agent for rubber is an indispensible product to maintain the efficiency of rubber production process and molding quality. It exerts excellent performance in separating a product from a mold after curing process.

Rubber release agent is used in various rubber molding processes. When used efficiently, it can form thin and uniformed protective film and stable surface thanks to its excellent heat resistance. Therefore, it can improve economics and productivity.

※ Dusting Agent

Rubber products before curing stage have the problem of their surfaces are stuck to each other during transportation or storage due to their high cohesiveness. Therefore, rubber dusting agent is an indispensible product to prevent this problem. This product doesn't affect the matter properties of rubber and completely prevents them from cohering to each other during transportation or storage. It is appliable to all kinds of rubber.

It does not hinder at all adhesion process following curing process.

> Precision and Special Chemistry > Mold Release Agent

> Precision and Special Chemistry > Mold Release Agent